Water leaks may seem like a small issue, but in industrial settings, they can quickly escalate into expensive, disruptive problems. To combat this risk, more industries are investing in automatic water shutoff valves—a reliable solution designed to detect water leaks and stop them in their tracks. These systems are not only essential for protecting critical equipment and infrastructure but also play a significant role in improving operational efficiency.

In this article, we’ll explore how auto water shutoff systems work, their core components, and why they are crucial for modern industrial applications. Whether you’re overseeing a manufacturing facility, managing a commercial operation, or simply seeking better leak protection, understanding this technology can help you make smarter decisions.

What Is an Automatic Water Shutoff Valve?

An automatic water shutoff valve is a safety device that monitors the flow of water through a pipe and automatically stops the flow when it detects a leak or abnormal water usage. These systems are often paired with sensors or flow meters to measure activity in real time.

Unlike manual valves, which require human intervention, automatic shutoff valves operate autonomously. This means that the moment a fault is detected—such as a burst pipe, fitting failure, or abnormal pressure—the valve will close instantly, minimizing the risk of water damage.

How Auto Shutoff Systems Detect Leaks

There are two primary methods that automatic water shutoff systems use to detect leaks:

1. Moisture Sensor-Based Detection

This type of system relies on sensors placed in leak-prone areas. When these sensors detect the presence of water, they send a signal to the shutoff valve, which then closes to stop the flow. These systems are commonly used in homes and office spaces where small leaks can go unnoticed.

2. Flow Monitoring and Anomaly Detection

Industrial-grade systems, such as the WeldSaver™ 6 by Proteus Industry, use advanced flow sensors to continuously monitor water usage. If the flow rate deviates significantly from the expected pattern—indicating a leak, blockage, or disconnection—the system automatically engages the shutoff valve. This type of detection is especially useful in environments with complex machinery or cooling systems where even small changes in water flow can be critical.

Core Components of an Auto Shutoff System

An effective automatic water shutoff valve system typically consists of the following components:

- Shutoff Valve: The physical device that opens or closes the flow of water.

- Control Unit: The brain of the system that receives input from sensors and controls the valve.

- Sensors: Either moisture or flow sensors that detect leaks or anomalies.

- Power Source: Most industrial systems use direct power, while some residential models rely on batteries or backup power systems.

These components work together to offer continuous protection—automating the response to water leaks and preventing potentially catastrophic failures.

Why Industries Need Auto Water Shutoff Systems

In industrial applications, water is often used in cooling processes, welding systems, and hydraulic machines. A leak or line failure can not only damage equipment but also disrupt production, compromise safety, and lead to costly downtime.

Here’s why installing an automatic water shutoff valve is a wise move for any facility:

1. Equipment Protection

Leaks can damage sensitive components, motors, and circuitry. By shutting off the water supply at the first sign of a problem, these systems prevent damage to valuable equipment.

2. Reduced Downtime

Production stops caused by water damage can be costly. Auto shutoff systems reduce the need for emergency repairs and help facilities maintain uptime.

3. Improved Safety

In some operations, water mixing with electrical equipment or hot surfaces can create serious hazards. These systems ensure leaks are stopped before they pose a danger.

4. Lower Maintenance Costs

Preventing leaks reduces wear on pipes, joints, and fittings. This results in fewer repairs, extending the life of your infrastructure.

5. Sustainability and Efficiency

Leaks often lead to water waste. By detecting and responding quickly, these systems help reduce water consumption—contributing to sustainability goals.

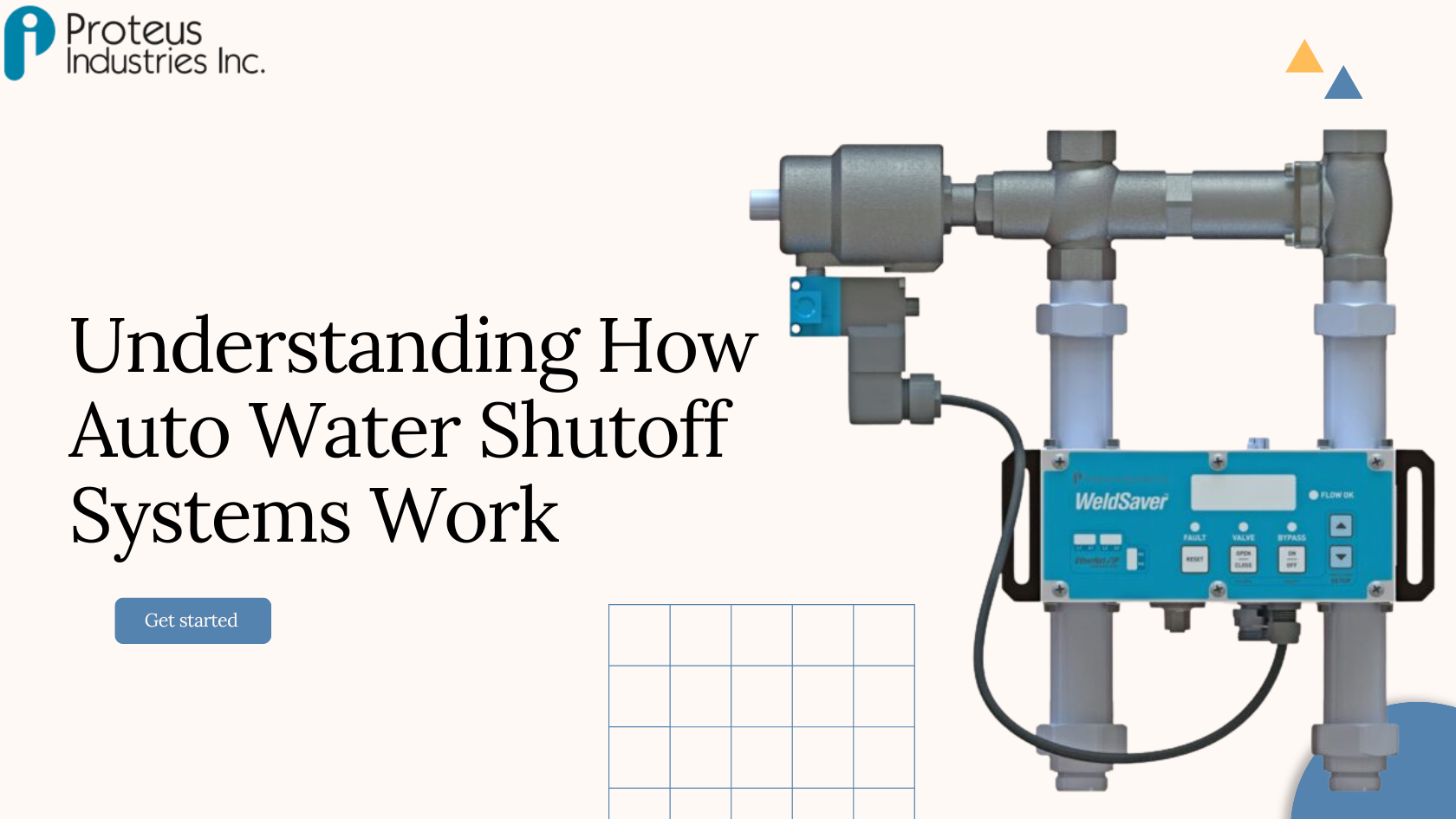

Industrial Solution Spotlight: WeldSaver™ 6

One of the most advanced solutions available for industrial leak detection is the WeldSaver™ 6, developed by Proteus Industry. This system is specifically designed for robotic and automated welding operations where coolant water is vital.

The WeldSaver™ 6 monitors coolant flow in real-time, detects leaks or disconnects instantly, and signals the automatic water shutoff valve to respond. Its intelligent design ensures that cooling systems remain efficient and that leaks are managed before they can lead to damage or loss of productivity.

This system integrates seamlessly with most industrial control environments and is trusted in manufacturing facilities where precision and protection are essential.

Choosing the Right Automatic Shutoff System

When selecting an automatic water shutoff valve for your facility, consider the following factors:

- Application Type: Is it for cooling systems, processing lines, or general plumbing?

- Response Time: How quickly does the system detect and shut off water?

- Sensor Compatibility: Does it support both moisture and flow-based sensors?

- Integration: Can it be easily integrated into your existing control systems?

- Durability: Is it built for industrial environments with high usage demands?

Investing in the right system ensures long-term protection and peace of mind.

Final Thoughts

Water damage can happen in seconds—but the right technology can stop it just as fast. An automatic water shutoff valve offers proactive protection by detecting problems early and acting instantly. In industries where water is essential to operations, such as manufacturing, electronics, and welding, having this level of control is not just helpful—it’s necessary.

Systems like the WeldSaver™ 6 from Proteus Industry showcase how intelligent design and automation can safeguard assets, maintain efficiency, and support sustainable operations. Whether you’re upgrading an old facility or building a new one, incorporating auto shutoff systems is a smart step toward modern water management.